Что такое ПЭТ?

What is PET and what is it served

with?

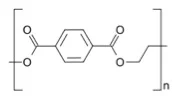

Polyethylene terephthalate - PET, PET (PET) is a

thermoplastic polyester used in the production of synthetic fibers, films and

plastic packaging.

PET is known to the world under other names - lavsan, dacron,

mylar, thermoplastic or polyester. Materials produced on the basis of

polyethylene terephthalate have an international name - PET. For the

Russian consumer today, two abbreviations are relevant: PET - when it comes to

polymer, PET - when it comes to products made from it.

International PET mark

PET containers are one of the most famous in

the world: plastic bottles, vials, cans and other containers are made of

polyethylene terephthalate. It is also widely used in medicine, mechanical

engineering, and clothing manufacturing.

PET

production

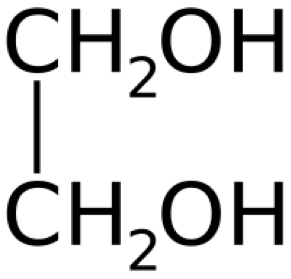

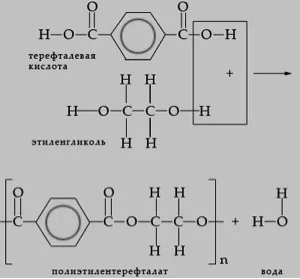

The raw materials for PET are terephthalic

acid dimethyl ester and ethylene glycol.

|

Colorless crystals of terephthalic acid are synthesized with ethylene

glycol (liquid) in a special apparatus at 260 degrees - a polyethylene

terephthalate melt is formed at the outlet.

The melt is extruded, cooled and

granulated or sent to fiber spinning. All the necessary dyes and additives

are introduced into the material during synthesis or into the resulting PET

melt. Commodity PET material at the outlet is granules with a size of 2-4

mm.

Polyethylene terephthalate is a high

molecular weight plastic polymer. It has nothing to do with poisonous low

molecular weight phthalate. Dibutyl phthalate plasticizer is not used in

the production of plastic containers, since polyethylene terephthalate itself

is very plastic.

PET can be in two

states:

-

amorphous state: a solid, transparent substance with a grayish-yellowish tint, passes into this state upon rapid cooling

-

crystalline state: solid, colorless, opaque substance, transitions to this state upon rapid cooling

PET has transparency, high strength, good plasticity, high barrier properties. This material lends itself to processing by drilling, sawing, milling. PET material retains all its characteristics at temperatures from -40 to +75 degrees.

Physical properties of PET

-

Thermal expansion coefficient (melt) - 6.55 x10 -4

-

Compressibility (melt), MPa - 6.99 x 106

-

Density, g / cm3: amorphous, crystalline - 1.370, 1.455

-

Dielectric constant (23 ° С, 1 kHz) - 3.25

-

Elongation at break,% - 12-55

-

Glass transition temperature, (amorphous, crystalline PET) - 67, 98 ° С

-

Melting point, ° С (amorphous, crystalline PET) - 225-275 ° С

-

Decomposition temperature - 350 ° С

-

Refractive index (Na line): amorphous, crystalline - 1.576, 1.640

-

Tensile strength, MPa - 172

-

Tensile modulus, MPa - 1.41x104

-

Moisture absorption of PET - 0.3%

-

Permissible residual moisture in PET - 0.02%

-

Frost resistance, up to -50 ° С

The invention of PET and the emergence of PET containers

PET was patented in 1941 by the

English company Calico Printers, which received the first synthetic

fiber. The copyright for PET was sold to DuPont and ICI, which created the

famous Mylar fibers for use in spacecraft.

Until the 60s of the twentieth

century, PET was used in the textile industry, later they began to produce

packaging film from it. In 1976, DuPont engineer Nathaniel White created

the world's first PET bottle.

In the USSR, work on obtaining PET was

carried out in 1949 at the Research Institute of Artificial Fibers. At the

place of obtaining the material - the Laboratory of Macromolecular Compounds of

the Academy of Sciences of the USSR - it was named "lavsan".

PET for bottle use in Russia appeared

only at zero. This is also the reason for the beginning of the study of

the material at the Research Institute of Plastics, which proved that PET is a

pure polymer and one of the most harmless types of plastic.

The first Russian PET plant started

operating in 2003 and quickly increased its volume. Today, there are four

such factories in Russia, and the food industry's needs for PET packaging are

satisfied by 95% - almost ideal economic indicators. By 2020, it is

expected to launch an import-substituting enterprise in Tatarstan - SafPet, the

Ivanovo polyester complex, as well as the Etana industrial complex in

Kabardino-Balkaria.

The production of PET packaging of all

shapes and sizes is the most significant field of PET application

today. PET containers are used for packing carbonated and mineral waters,

vegetable oil, sauces, juices, fermented milk products, beer, kvass, perfumery,

household chemicals, pharmaceutical products. At the end of 2016, Russia

produced 534 thousand tons of PET (7% more than a year earlier), imports

amounted to 108 thousand tons, exports - 36 thousand tons.

PET and ecology

PET containers have gained popularity

due to their ease of use, weight, low cost and, most importantly, they are

completely inert to the products packaged in them.

PET belongs to the 5th, safest, waste

class. The process of production and circulation of plastic containers

does not require a large amount of electricity, which also minimizes CO2

emissions into the atmosphere.

PET containers decompose in landfills

for 150 years (for example, it takes 500 years for an aluminum can to

decompose, and more than a thousand years for a glass can). In

addition, special

bacteria Ideonella

sakaiensis 201-F6 is capable of decomposing PET

into its original components -

to terephthalic

acid and ethylene

glycol .

PET recycling

potential

PET packaging is 100%

recyclable. Recycled PET material is used, among other things, for

packaging products, since the production of plastic containers is possible both

from “primary” raw materials and from “secondary” ones.

The technology for recycling plastic

packaging is called bottle-to-bottle. Old bottles are collected, sorted by

color, washed, crushed and processed, melting and getting the same PET

granulate, only colored. And the granules are again used for the

production of PET bottles.

Flex or pellets are also made from

recycled PET. Flex is used to produce bristles for brushes of cleaning

machines and car washes, packing tape, film, roof tiles, paving slabs. And

from pellets - filler for sleeping bags and geogrid for roads.

At the same time, recycling plastic

bottles saves 50-60% of the energy that would be needed to produce a product

from new materials.